The Evolution of Barcodes

On June 26th, 1974, in a supermarket located in Troy, Ohio, a single pack of Wrigley’s Juicy Fruit chewing gum was “scanned”. This was the very first object with a barcode to be scanned using modern barcode technology: bouncing light off of the barcode and generating an electrical signal based on the intensity of the returning light. This pack of gum was just the first of billions of products using barcode technology. What led to this legendary accomplishment? Two men, Bernard Silver and Norman Joseph Woodland, and their decades of work helped usher in a new era of cataloging. Undoubtedly, these men were two of the larger contributors to creating the Information Age. In this section of a three-part series, we examine the history of barcodes and how they changed the world.

Punch Cards to Progress

Prior to the advent of barcodes, grocers were desperately in need of a system to track inventory and purchases. Punch cards, developed by the United States government for the 1890 Census, were the best hope they had in terms of an automated process. Unfortunately, the machines that read punch cards were, at the time, horribly bulky and expensive. Grocery stores needed a way to track merchandise automatically; before barcodes and scanners, stores would shut down to count every single piece of merchandise by hand, accounting for what they had in the store. This process was expensive and time-consuming, often, at least momentarily, stunting business growth.

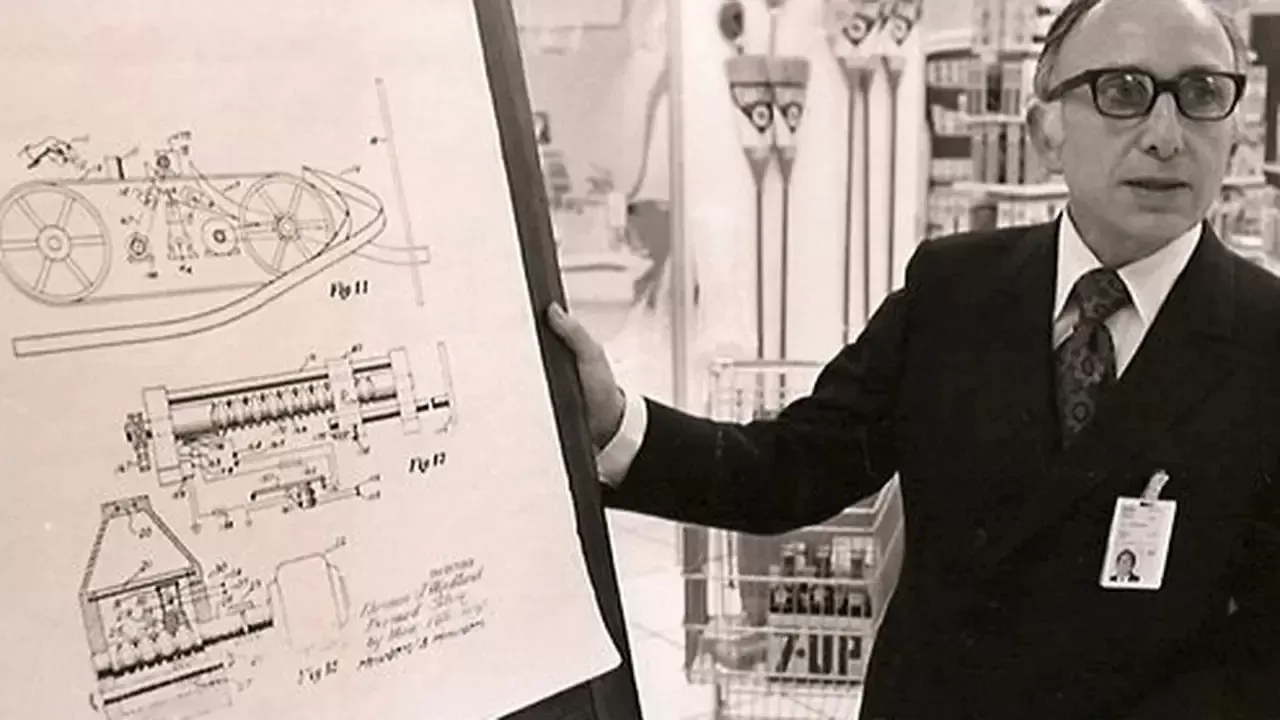

It was this problem that created the idea for Bernard Silver, a graduate student with a Bachelor’s Degree at Drexel Institute of Technology. In the halls of the institute, Silver overheard the owner of a local chain of grocery stores asking a dean to undertake research regarding a method to read product information automatically at checkout, in order to better track inventory. While the dean denied the owner, Silver was intrigued and brought the idea to his friend Norman Joseph Woodland, another graduate student and teacher at Drexel. Woodland quickly became absorbed with the idea, even dropping out of school to focus on it.

His first ideas involved using inks that illuminated under ultraviolet light. It wasn’t a perfect plan, having a variety of problems ranging from expensive printing to ink instability, but Woodland was convinced this was an idea with huge potential.

One day, sitting on the beach near his grandfather’s house in Florida, Woodland had a breakthrough. Woodland, a Boy Scout in his childhood, was familiar with Morse code. Sitting on the beach, he traced outlines in the sand. Much later, to Smithsonian Magazine in 1999, he would describe the experience as a “fairy tale.”

“I poked my four fingers into the sand and for whatever reason — I didn’t know — I pulled my hand toward me and drew four lines. I said: ‘Golly! Now I have four lines, and they could be wide lines and narrow lines instead of dots and dashes.’ ”

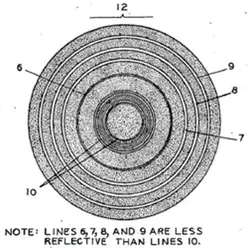

But Woodland wasn’t done; “Only seconds later,” Mr. Woodland continued, “I took my four fingers — they were still in the sand — and I swept them around into a full circle.” Thus, Woodland’s design for the barcode was born.

Woodland preferred this circular design, later coined the ‘bull’s-eye code,’ for its omnidirectionality. Three years later, on October 7th, 1952, Woodland and Silver were awarded a US patent for their invention, which they named ‘Classifying Apparatus and Method.’

Problems, Development, and Growth

This new invention was sorely underdeveloped, and suffered from the same problems the punch card machine did: it was bulky, unwieldy, and expensive. Subsequently, in 1962, the two sold their patent to Philco for $15,000. The following year, Bernard Silver died at the tragically young age of 38. Nevertheless, this did not end the development of the technology; in 1971, Philco sold the patent to RCA, which jolted other companies into action.

Between 1962 and 1971, the development of barcode technology was largely done by the railroad industry. Freight cars traversed huge areas of the country, were frequently loaned to other lines, and were generally difficult to keep track of. Railroad companies desperately needed a way to keep track of the mass of cars they used, and barcodes presented a way for their ideas to become a reality. The Sylvania Corporation put forward technology similar to barcodes, but instead of the black and white stripes we use today, it used orange and blue stripes, made of a reflective material, put on rail cars. Sensors would shine a light onto the code, and gather information based on the patterns of the material. However, Sylvania didn’t see the future of barcodes used in stores across the world, so a competing company, Computer Identics, quickly moved in.

A Future Found in Lasers

Computer Identics proved that barcodes had global potential by using lasers. Lasers, a barely profitable industry at the time, solved Silver and Woodland’s problem of bulkiness and heat problems that their 500W lamp caused when exposed to the paper and the ink of the barcode. By the 1970s, Computer Identics showed the technology Woodland had dreamed up was feasible and close to commercial maturity. This encouraged several other companies to look into the burgeoning technology: primarily, the Radio Corporation of America (RCA).

RCA would be the first company to demonstrate the power of barcodes in a grocery industry setting. At a grocery industry meeting in 1971, visitors were given a small tin with a bull’s-eye code, and a prize if the barcode machine correctly identified the code on top of their tin. IBM executives at this meeting saw the number of people the RCA booth was drawing and immediately began pushing their own advancements in technology. Woodland, who had taken a job working for IBM after selling his patent, was moved to a facility in North Carolina to lead development.

By 1972, RCA had secured an 18-month barcode testing period with Kroger grocery stores but was running into serious problems with their bull’s-eye codes. When printing, the ink had the possibility to smear upwards, ruining a large amount of the code and making it unreadable. Woodland’s IBM team, however, was creating the barcode we recognize today: a series of black bars in a row. This code called the IBM UPC (Universal Product Code), didn’t have the problems of ink smearing; if the ink smeared, it would simply make the code slightly “longer”, but still represent the same code. And so, on April 3rd, 1973, the National Association of Food Chains (NAFC) accepted the UPC as the industry standard.

Stepping Forward

Convincing a multitude of businesses that they would benefit from barcode technology was never easy. The equipment used for scanning and even creating barcodes was still expensive. It was a slow process, and even by 1977, four years after the UPC was accepted, only 200 stores had scanning technology implemented. The strong success of the scanners within the stores prompted many other businesses to change as well; the return on the investment for a scanner was a strong 41.5%. By 1980, over 8000 stores per year were converting.

This wasn’t the end of improvements in technology. Over the upcoming decades, many other types of codes were created, including two-dimensional (“2-d”) barcodes. To learn more about the quickly changing industry, check out the next sequence of the article, “Evolution of Barcodes: 1-D to 2-D”.